COVID-19 and the challenge of shipping vaccines are part of the conversation these days, so we are excited to host Scott Whyte, the Chief Digital Officer at AeroSafe Global.

AeroSafe delivers cold-chain services to the world’s leading biopharma companies. In this interview, Scott educates us of the innovations his company has done to elevate the standard of cold shipping, what they are doing differently and better, and how they are helping improve patients’ lives around the world.

He shares how AeroSafe is the only company selected by NASA to ship cold chain materials to the space station. He also talks of the long list of benefits his company delivers to their clients, including cost-reduction, environmental savings, and many more.

If you’d like to get updated on what’s going on in the cold chain industry and find out how AeroSafe can protect vaccines, you’ll enjoy this podcast!

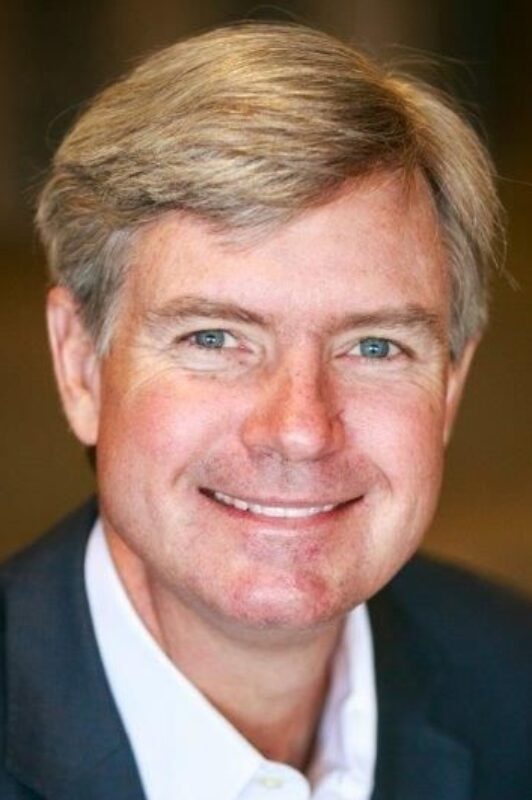

About Scott Whyte

Scott Whyte is the Chief Digital Officer at AeroSafe Global. He is a veteran life science and health I.T. leader with over twenty-five years of experience serving the nation’s largest life science provider, payer, and health solutions organizations.

Prior to joining Aero Safe, Scott was the Chief Strategy Officer at Clear Data, the leading life sciences and health care cloud automation and security company where he helped drive 30X growth. He has also served as the I.T. Vice President at Common Spirit Health, Vice President and CIO of Phoenix Children’s Hospital, and helped build the health care practices at EY, Siemens Health Care, and Capgemini.

COVID Vaccine Delivery Challenges & Solutions with Scott Whyte, Chief Digital Officer at AeroSafe Global was automatically transcribed by Sonix with the latest audio-to-text algorithms. This transcript may contain errors. Sonix is the best audio automated transcription service in 2020. Our automated transcription algorithms works with many of the popular audio file formats.

Saul Marquez:

Hey, Outcomes Rocket listeners, Saul Marquez here, I get what a phenomenal asset a podcast could be for your business and also how frustrating it is to navigate editing and production, monetization, and achieving the ROI you’re looking for. Technical busywork shouldn’t stop you from getting your genius into the world, though. You should be able to build your brand easily with the professional podcast that gets attention. A patched-up podcast could ruin your business. Let us do the technical busy work behind the scenes while you share your genius on the mic and take the industry stage. Visit smoothpodcasting.com to learn more. That’s smoothpodcasting.com to learn more.

Saul Marquez:

Welcome back to the Outcomes Rocket, Saul Marquez here. Today, I have the privilege of hosting Scott Whyte. He is the Chief Digital Officer at AeroSafe Global. Scott is a veteran life science and health I.T. leader with over twenty-five years of experience serving the nation’s largest life science provider, payer, and health solutions organizations. At Aero Safe Global, he’s responsible for driving digital innovation, partner and customer relationships, and more. Scott’s also actively advising early-stage health technology companies and investors and health tech. Prior to joining Aero Safe, Scott was the Chief Strategy Officer at Clear Data, the leading life sciences and health care cloud automation and security company where he helped drive 30X growth. In prior roles, Scott served as the I.T. Vice President at Common Spirit Health, Vice President and CIO of Phoenix Children’s Hospital, and 17 years helping build the health care practices at EY, Siemens Health Care, and Capgemini, serving hospitals, health insurers, and life science companies. Scott has spoken nationally on topics including accountable care, cloud health information exchanges, digital engagement, and genomics. His background is impressive and also multifaceted. And so I think everybody is going to enjoy our conversation with Scott today. Scott, thank you so much for joining us.

Scott Whyte:

Saul, it is great to be with you today. Really excited to talk with you.

Saul Marquez:

Yeah, likewise, Scott. And so before we dive into our Aero Safe Global in the work that you guys are doing there, I want to learn more about you, Scott, and have the listeners learn about you and what inspires your work in health care.

Scott Whyte:

Good. So I think it would be good to go back in the early days. I was so excited about technology, was a programmer early in high school. These are the days when Apple and PCs were just coming out and studied information systems and was excited to apply technology to make businesses better. And I was not actually interested in health care, but my consulting organization assigns me to a project at Kaiser in Northern California, helped design, implement and go live with the system in a brand new hospital in Northern California. And I completely caught the bug. So working with physicians and nurses, lab and pharmacy, radiology people, and the beauty and complexity of the human body and medicine, along with having some problems to solve. I mean, there’s really some broken workflows and a need for improved information sharing just pulled me in. And that’s been a twenty-five to now thirty-year journey of wrestling with problems in health care. And it inspires me because there are still illnesses and diseases and provider burnout. There are so many problems that we need to work on and to apply technology to make things better. And that inspires me.

Saul Marquez:

Yeah, that’s so interesting, Scott. And you’ve been through a lot. And so now you’re doing some very interesting work at Aero Safe. So talk to us about what you guys are up to there and what exactly you’re doing to add value to the health care ecosystem.

Scott Whyte:

Well, it is so relevant to today. Aero Safe Global focuses on cold chain shipping for pharmaceuticals. But that’s a very important message that even amongst health care professionals, very few knew about it until right now it’s in the national news because of the COVID challenge and the challenge of shipping vaccines, some of which need to be negative 70 degrees Celsius. And so cold chain is front and center even in the mainstream media. So I’m thankful to be a part of that to, as we speak, be involved in the delivery of the vaccines all over the world. And my role on the digital side is to connect our digital cold chain solutions with other parts of the health care ecosystem. And so even just this morning, I was talking with a global medical device company about ways to sort of bridge some of the big gaps and problems that we have between the vaccine and the devices and other elements of the system that really all need to come together ultimately in order to vaccinate people and push back this awful a pandemic.

Saul Marquez:

Yeah, that’s really interesting, Scott. And cold chain logistics, basically keeping everything cold right. I mean, keeping it at the temperature through the entire supply chain that it needs to be.

Scott Whyte:

Yeah. Yeah, that’s right. So we, for instance, work with a controlled room temperature. So it’s really across the spectrum from something that I live in Phoenix, for instance. And this past summer we had 50 days over one hundred and fifteen degrees. So even if you’re trying to ship something that doesn’t need to be really super cold, you need to protect it from that that environmental temperature and so we can do that and the same can go to the other extreme, we ship in Canada in the winter or other very cold places that you can’t actually have to get some therapies because you don’t want them to get too cold. So we can do a controlled room temperature, we can ship it refrigerated, we can do frozen, and in the case of this, one of the vaccines in the news right now, we can ship at full frozen to and we ship parcels. In other words, we ship all the way to patients’ homes and to physician clinics and county health facilities and hospitals and things like that. We ship not just vaccines, but oncology therapies and insulin, for instance, different more and more therapies or biologics that need to be kept at a certain temperature ranges.

Saul Marquez:

That is fascinating. And the environment to give us a lot of challenges. And I can imagine it’s critical to get these things right. What would you say makes what you do different and better than what’s available today?

Scott Whyte:

Well, yeah, I was drawn to AeroSafe for a number of reasons, and one of them is just amazing in engineering. So AeroSafe has been at this coaching work for 15 years and the engineering of the insulation, for instance, is it’s over the top. It’s proprietary, it’s patented are our boxes are actually used by NASA. We’re the only ones selected by NASA to ship cold chain materials to the space station. So it’s incredibly efficient. It’s an incredibly thin material that it effectively if you think about your own home insulation, we can get half an inch we can get R50, which would take several feet of insulation in your home. So amazing engineering. Because of that engineering, we’ve had zero excursions and that’s the term used for something gone out of the temperature bound. We’ve had over those 15 years, zero excursions. So it’s quite effective, which means that patients are taking care of. That means that the therapies that they get are they’re going to work, know at least they’re not going have a problem because the temperature was out of bounds and because that engineering and that material, that insulation is so thin, our boxes can be smaller and lighter, which means there’s reduced cost. So it’s clinically better, but it’s also more cost-effective. We also have this amazing return process. We call it a loop and aero loop. And using our people process and technology, we are able to get back ninety-eight to ninety-nine percent of our boxes that we shipped out. So that’s a huge environmental saving.

Scott Whyte:

So I can tell you just on a personal experience, we have three type 1 diabetics in our family, so we get insulin shipped to our house in cardboard boxes filled with styrofoam and then sort of those kinds of cooler ice package things that you get in a huge lunchbox or something like that, all a complete waste so that styrofoam is constantly thrown away. And those freezer packs, those are never reused either. But with AeroSafe’s process and the fact that we get that material back, the insulation panels we get to reuse, and then the cooling materials are typically a phase change material and we get to reuse those as well. So we have sixty-five percent less CO2. Ninety-eight percent reduction in landfill compared to the other packaging offices option. So there are huge environmental benefits. So the engineering, the clinical quality of excursions, the environmental advantages are excited about you excite me. But the other final piece, of course, is my personal responsibility. That’s the digital engagement and the innovation because we get these boxes back through this return loop we’re able to add additional Internet of Things, sensors that can understand the ambient temperature and temperature of the payload in therapy. And there are ways that we can bar code and connect the box to other workflows again to squeeze out waste and increase clinical quality so and really improve workflow for providers and the whole ecosystem. So I’m really excited about building upon the platform that we have in that way.

Saul Marquez:

That’s really interesting, Scott. And so how are people and practices, businesses sending this back? Like how does that work?

Scott Whyte:

So we have engineered the boxes so that the flaps, you open the box up and it’s got your to address, et cetera. And then there are instructions where you close it back. The return label is all ready to go. And so. Yep. And so if it’s a physician’s office, there are instructions. They just put it outside their door and UPS and FedEx or something picks that up. But we also have systems and databases that allow us to contact those individuals of our contact databases are actually even more accurate than our pharmaceutical customers are so, partly because we have to actually talk with people or email them and we work with them to make sure we get those boxes back. So it really is truly it’s a people, process, and technology that we’ve built up over years. So we absolutely excel in this particular area, which is really important for this element of reuse. And actually, I mean, just on the COVID vaccine side, we’ve done some calculations, if we will be several billion doses, ultimately that will be distributed. But if we just take one billion doses, we’re using our process. We can save three million kilograms of landfill, three hundred and forty million gallons of water, one hundred and twenty million kilograms of CO2 reduction. So real, real, true, and significant environmental savings we have through this process.

Saul Marquez:

Well, and not to mention the savings with less waste Right.. Or what would you call excursions?

Scott Whyte:

Oh, totally. Yeah. Yeah. I mean, that is again, particularly here, again it’s been in the news. Is it even possible how is this going to work? And our boxes can work across temperature ranges. But for one of those, it’s been in the news out of the box design that will last at least 10 days as a tabletop ultra freezer. So in other words, a provider doesn’t have to buy an expensive freezer in order to keep the therapy down, to make it 60 or colder. They can just use our box. And that box will continue to keep the vaccine, in this case, cold for that time period. And then you take it out and it can be refrigerated and kept for even an additional day. So we have other solutions that can move it from the box to an insulated case. And then the case you can take out to a nursing home or a remote clinic. And again, we can have that case monitor the temperature and keep the therapy at the right refrigerator temperature for the time that you’re in transit for a nurse or pharmacist or whoever is going to be actually administering the vaccine. So lots of great solutions that we have to actually get to the patients and administer.

Scott Whyte:

And, you know, I would say I think it’s particularly important now because there’s been a lot of politics and good news and there’s been a lot of fear. And in fact, I even saw one survey where 40 percent of the nurses in one state did not want to take a vaccine, which is really concerning. So from my behind the curtain view of working with some of these vaccine providers now and to see the rigorous engineering that our solutions and qualification and testing and it’s amazing what goes into just our box solution and the evidence that we have to show that demonstrates that it works. All that’s been done. But there are some people who are reluctant. And I think if we can get the message out to let people know that the different elements in terms of the vaccine development, the clinical trials, and then very importantly on this kind of wild card in the news about the shipping and keeping a cold, that we can do it. We’ve just we’ve got a track record of doing it. And people can have confidence that we’ll have greater take up of the vaccine and less vaccine hesitancy, which is going to be important for all of us.

Saul Marquez:

Totally agree, Scott. And these are the things that we typically don’t think about and really glad that Scott is here to educate us and how these things are being done and specifically how AeroSafe Global is doing it better and different. And so what would you say? I mean, it’s clear right. You’re improving outcomes by getting these vaccines to us in the state that they need to be. And as you’ve taken some thought into the approaches that you guys are doing, what would you say is one of the biggest setbacks that you’ve experienced and key learning that came out of that boy?

Scott Whyte:

There’s been, as you can imagine, a number of setbacks. I reflect on my career. And I think there have been different times when I should have been bolder and taken more risk. And for those who have known me and worked on my teams, they know that I do try to I have taken an appropriate risk in many instances. But there are some times where I probably should have taken more. I think all of us in health care, that’s good advice to be bold and specifically more recently, the temperature duration. It’s a long time to try to get up to ten days or two weeks at this low temperature and in this case where we’re using dry ice and to make sure we have a supply of dry ice in that box and shipping materials are going to work, that it’s very easy to handle for a provider. That’s another element that we want nurser to be able to reach into a box and then pull out vials of the vaccine in order to administer that. Ideally, the person wouldn’t have. I have to touch dry ice because you’ve got to have gloves on to prevent a dry ice burn. So we’ve got a lot of work. So I would say, I don’t know I would call them setbacks, but certain obstacles and challenges. Absolutely, to come up with an engineer, a solution to do this and really think through the requirements to think through the shock and vibration, to think through the security. How do we make sure this vaccine is like gold. How do we make sure this vaccine is tracked and know where it is from a GPS perspective that we actually monitor the temperature and know that it’s safe across the whole journey. So lots and lots of really challenging requirements that I think for us that have been working on health care for a long time, I think really near that that excites us to be able to have some challenges to have some really big problems to solve. This is a good thing. I think we’re blessed to have big problems to solve and we’ve wrestled with them and come up with a great solution. And we actually have evidence to show that it’s a great solution. And that’s very rewarding.

Saul Marquez:

Yeah, I would say so. And as you reflect on some of the comments you made earlier there where we’re working and helping people be more confident and I’ll throw myself in there to right. people, including myself and the listeners that are a little hesitant about taking the vaccine for one reason or another. It’s good to have this type of certainty around at least the supply chain process. What excites you the most today, Scott?

Scott Whyte:

So I truly am excited about the digital connections to break down silos, improve care, and just squeeze out the cost. And I can see that this has been an untapped part of the pharmaceutical supply chain. There certainly been there’s a great foundation is some good work that has been done. But I think the possibilities are absolutely tremendous. And this has been done across the industry. As we look at food safety, for instance, some of the blockchain initiatives that have been implemented to prevent some bad bugs, getting through our food supply, to be able to quickly identify those and understand really the provenance of where the food has been all the way along. That’s exciting. That hasn’t really yet been applied to, you know, one might say, as certainly as critical as the food supplies are in our medicine medical supply chain. So I think there’s that’s an example of digital innovation. We can compare this in our case, a box the shipper with this amazing engineering and the delivery of physical medicine and blends that with some digital solutions. And it’s a time when the medicine is right in front of the patient and it’s right in front of a provider.

Scott Whyte:

And so there are some very exciting things that we’re working on in that space. And to be able to deliver medical content to a physician that is up to date instead of a printed piece of paper, we’re able to get them the most recent medical articles related to this therapy or a particular diagnosis that’s exciting to be able to share with them, updated medication, administration information to share with patients of things that they might need to look for in terms of reactions to the medication and care. Well, well, on that particular therapy, we can present that to the patients now. So there are all kinds of digital innovations that some of which we started and some of which are planned. There are partnerships with other people in the ecosystem that can be accelerated via these digital innovations, like the example I use with a medical device company to really break down silos, in the end, to make life better for providers who are on the front lines and better for the patient. So that’s, you asked what makes me excited, I hope my enthusiasm is infectious. I think I really am excited about that.

Saul Marquez:

Yes, it certainly is, Scott. And there is a lot to be excited about. Well, we do have the challenges that we’ve been presented with. As Scott said, you know, some of those challenges are also a blessing because they’re making us better. And how we respond to that call is what will define who we are tomorrow and how we deal with these challenges moving forward. And what a great time to discuss these cold logistics and during this time. So I can’t thank you enough. Scott, before we conclude, I’d love if you could just share a closing thought with the listeners and then the best place where they could visit you and learn more about what you guys are up to.

Scott Whyte:

Absolutely Saul. Thank you so much. It really has been good to talk with you and important to share these cold chain innovations and some confidence, I think, that we can all have as part of this process. In terms of closing thoughts, I would challenge us all to look for hard and important problems to solve and to find like-minded colleagues to work with shoulder to shoulder and then to go forth, In some cases, I might be one of those people, so if you need like-minded colleagues, you could reach me at swhyte@aerosafeglobal.com. You can also absolutely find me on LinkedIn. Scott Whyte. And Saul, thank you again. Really great to talk to you.

Saul Marquez:

A big pleasure, Scott. Thank you for visiting with us. And certainly, look forward to having all these vaccines reach their intended destinations safely with your help. So thanks for spending time with us today.

Scott Whyte:

Absolutely. Great to talk with you.

Saul Marquez:

Hey, everyone. Saul Marquez here. Have you launched your podcast already and discovered what a pain it can be to keep up with editing, production, show notes, transcripts, and operations? What if you could turn over the keys to your podcast busywork while you do the fun stuff like expanding your network and taking the industry stage? Let us edit your first episode for free so you can experience the freedom visit smoothpodcasting.com to learn more. That smoothpodcasting.com to learn more.

Sonix uses cutting-edge artificial intelligence to convert your mp3 files to text.

Sonix has the world’s best audio transcription platform with features focused on collaboration. Automated transcription is much more accurate if you upload high quality audio. Here’s how to capture high quality audio. Transcription is now more accurate and more affordable. Are you a podcaster looking for automated transcription? Sonix can help you better transcribe your podcast episodes. Rapid advancements in speech-to-text technology has made transcription a whole lot easier. Automated transcription with the best customer support team to help you at every step of the way.

Automated algorithms have improved a lot over the past decade. Do you have a lot of background noise in your audio files? Here’s how you can remove background audio noise for free. Sonix takes transcription to a whole new level. Do you have a podcast? Here’s how to automatically transcribe your podcasts with Sonix.

Sonix is the best online audio transcription software in 2020—it’s fast, easy, and affordable.

If you are looking for a great way to convert your audio to text, try Sonix today.

Things You’ll Learn

Resources:

swhyte@aerosafeglobal.com